Venturi Steam Trap

Hits : 3845 |

A steam trap is a self-contained valve which automatically drains the condensate from steam containing enclosure while remaining tight to live steam, or if necessary, allowing steam to flow at a controlled or adjusted rate. Most steam traps will also pass non-condensable gases while remaining tight to live steam. Effective removal of condensate by a trap from a steam system is important for maintaining the performance of process equipment, as well as ensuring safe operation of the system.

Venturi Steam Trap

A steam trap is a self-contained valve which automatically drains the condensate from steam containing enclosure while remaining tight to live steam, or if necessary, allowing steam to flow at a controlled or adjusted rate. Most steam traps will also pass non-condensable gases while remaining tight to live steam. Effective removal of condensate by a trap from a steam system is important for maintaining the performance of process equipment, as well as ensuring safe operation of the system.

There are four main types of steam traps: mechanical, thermostatic, thermodynamic, and fixed orifice. Each type has unique advantages and disadvantages. However, the useful life under the surface varies widely, and the annual failure rate of traditional four types of steam traps ranges from 8% to 17%. Overtime, mechanical, thermostatic, and thermodynamic types of steam traps can fail in either the open or closed position, whereas fixed orifice type of steam traps can only fail closed.

Venturi steam trap technology is a new development in the steam trap technologies to address some of the shortfalls of the four types of steam traps. Venturi traps do not contain or rely on moving parts to reduced failure rates leading to longer operational life than mechanical steam traps.

Mechanism of Venturi Steam Trap

The potential for eliminating the steam loss through failed open traps, in traditional four types described above, is significant and worth further appraisal of venturi technology.

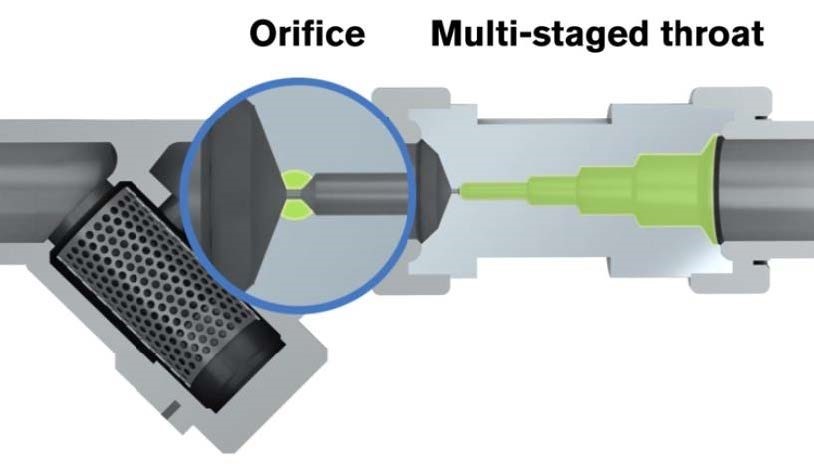

Venturi traps are comprised of a fixed port venturi nozzle and an orifice. A venturi is a piece of narrow tube between wider sections, so named because it creates the venturi effect where the velocity of a fluid passing through it increases as the cross-sectional area decreases with the static pressure correspondingly decreasing. Fluid condensate accelerates to pass through the orifice and drops in pressure, partially filling the orifice with condensate. Flash steam, which is produced from the saturated water under decreasing pressure in the venturi, expands in volume to limit the amount of fluid that may subsequently discharge through the orifice. Steam flash is the thermodynamic phenomenon that prevents large amounts of steam from leaking out of the trap when the orifice is not full of condensate. In the event an orifice is occupied by less than 68% condensate, a small amount of steam will pass through and flash (e.g., raise the temperature of) the saturated condensate, creating the backpressure that chokes further steam loss. It is recommended to include a strainer and blowdown valve, or a drip-leg, upstream of the small venturi nozzle, to remove the dirt and scale buildup over time. Also cleaning the strainer at least once a year or on a regular maintenance schedule based upon amount of particulates in the steam supply is advised.

Applications of Venturi Steam Trap

Much like mechanical-type trap, venturi steam trap has variability of the steam load by application, ranging from high variability in space heating steam processes to low variability (e.g., consistent steam loads) in some industrial applications such as paper drying. Since the trap can handle variable loads and accommodate wide load changes it is suitable for a large range of applications.

Advantages:

- No moving parts in the steam trap.

- Suitable for high-pressure steam system application.

- Highly durable and can withstand water hammering.

- No damage by freezing.

- Superheated steam can also be managed well without loss of its efficiency.

- Can be installed in any position.

Limitations:

-

Venturi Size must be selected carefully, each steam trap needs special attention as per its location and size.

-

It can’t respond to varying condensate loads.

-

Oversized venturi can make the steam trap inefficient.

-

Dirt particles of steam affect its performance.

-

If no condensate is present in the trap body, this allows steam to pass from the outlet.

-

Poor air discharge

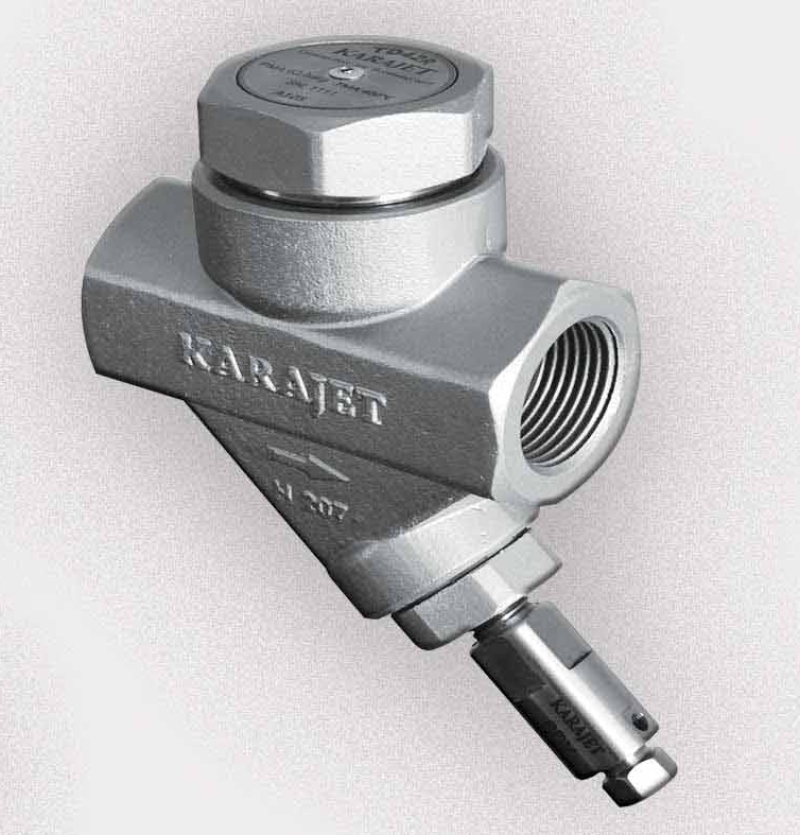

Karajet Venturi Steam Trap:

In Karajet, it is our honor to be commited to the high efficency of our products.also for Venturi steam traps we are using the High tech design to make the trap system more and more effective.

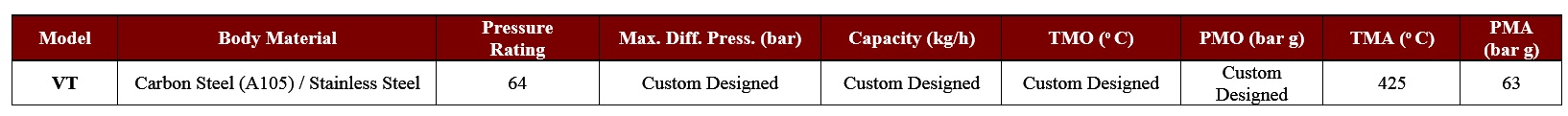

You can see the different types of Venturi steam traps in the table below:

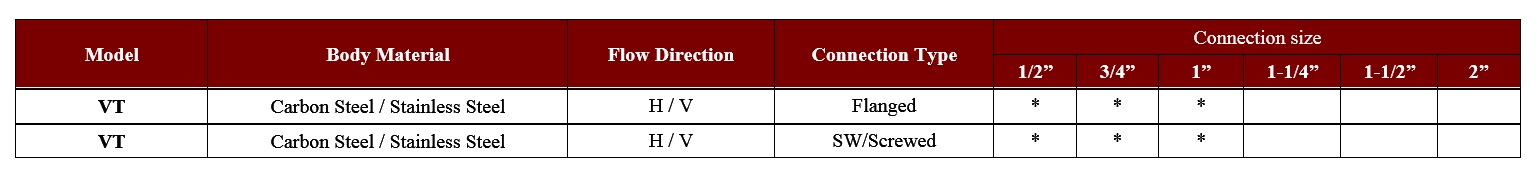

Also according to the Size and Connection you can see Venturi steam traps types in karajet here:

To know more about Venturi steam traps, we would like to suggest yu our Catalogue here: