Thermodynamic Steam Trap

Hits : 4102 |

Thermodynamic steam traps, also called disc traps, operate as a function of velocity.to know more about them, thermodynamic steam traps are operated by the principle of thermodynamics. The main principle behind the operation of thermodynamic steam traps is Bernoulli's principle.

we Suggest you to read below and know more about these steam traps:

Thermodynamic steam trap

What is Thermodynamic Steam Trap?

Thermodynamic steam traps are operated by the principle of thermodynamics. The main principle behind the operation of thermodynamic steam traps is Bernoulli's principle. Thermodynamic Traps are the most widely used steam traps for removing condensate from main lines largely due to their small size, wide pressure range, one moving part, and resistance to water hammer and corrosion. Because operation of each model depends on the manufacturer’s seat and disc design, results obtained by the user may vary widely.

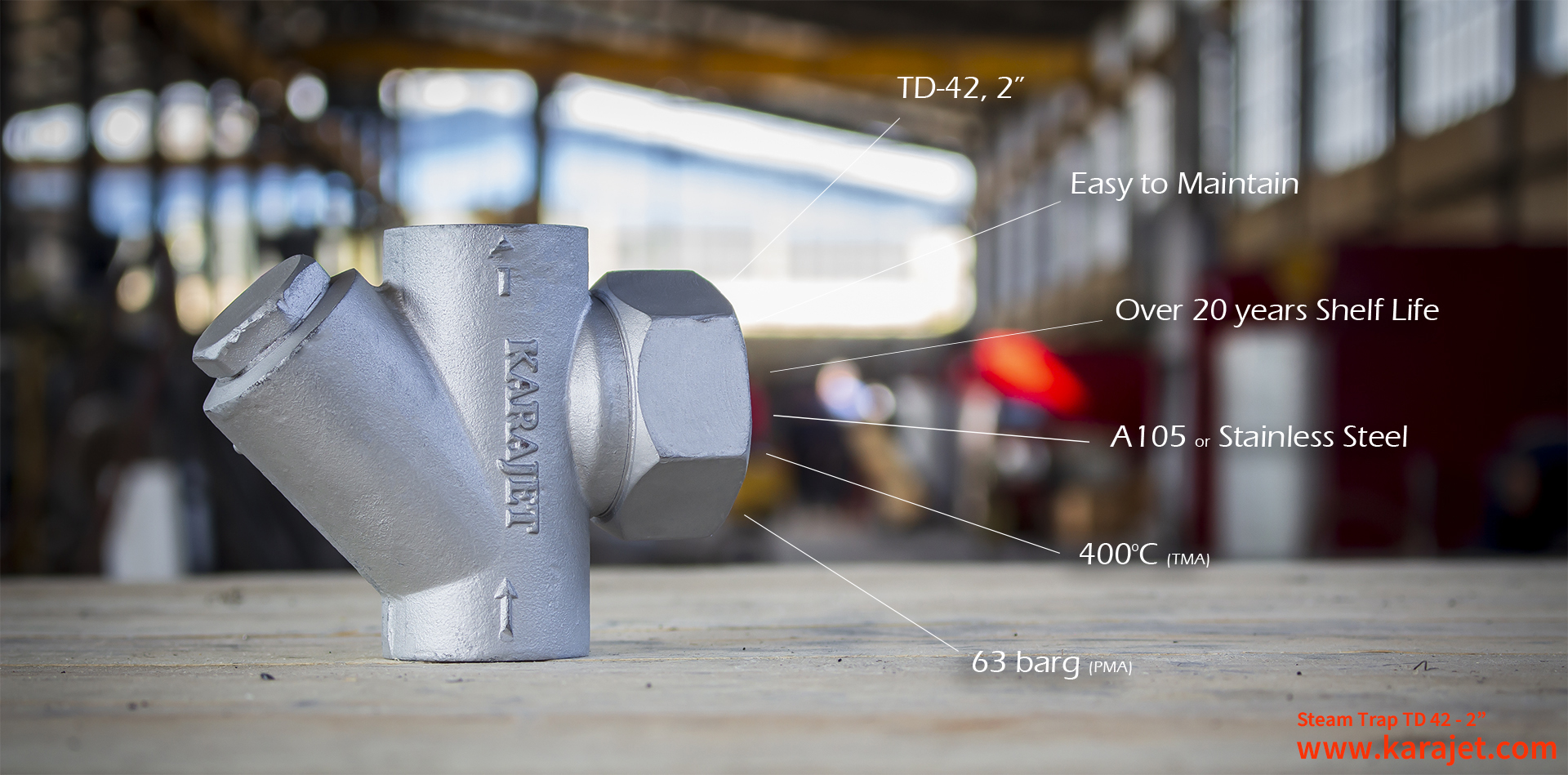

You can see an example of thermodynamic steam trap here

How do they Work?

Thermodynamic steam traps, also called disc traps, operate as a function of velocity

Operating Pressure Range: 0.7 to 120 barg

Operating Temperature Range: 0 to 550 oC

Capacity Range: Up to 1800 kg/h

Advantages of Thermodynamic Steam Traps

- No requirement for any adjustment of calibration

- Compact, simple, and lightweight body design

- Can be used for high-pressure and high-temperature steam

- No specific installation orientation requirement

- Highly durable and withstand with water hammering

- Performance can be easily checked in the field

What are the Limitation of Thermodynamic Steam Trap?

- During the start, its air handling capability is very less that can cause a stuck disc.

- Excessive back pressure in the return system can prevent the disc to close.

- High noise during condensate discharge.

- Dirt can increase the work cycle rate that increases the wear of the disc.

- Sensitive to environmental conditions. Cold weather can lead to improper working of the trap.

Karajet Thermodynamic Steam Traps

In Karajet, it is our honor to be commited to the high efficency of our products.also for thermodynamic steam traps we are using the High tech design to make the trap system more and more effective.

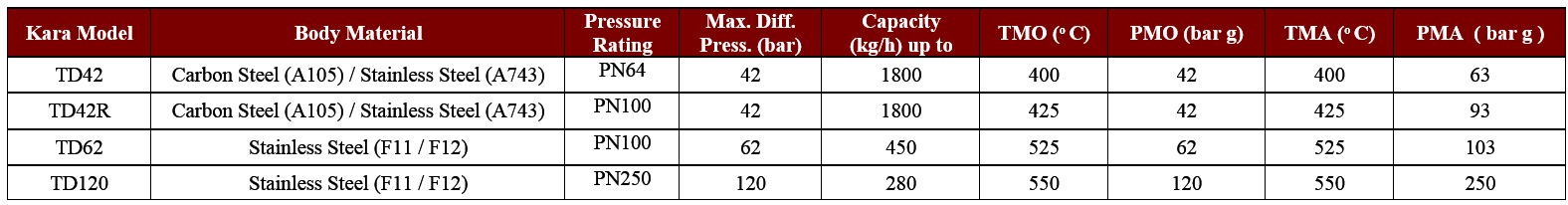

You can see the different types of thermodynamic steam traps in the table below:

TD42 / TD42R

Thermodynamic steam trap with built-in strainer for use in applications with up to 42 barg differential pressure. It can be manufactured with a removable seat (TD42R) for easier maintenance and can be equipped with a bimetal air ring for better air ventilation.

TD62

Thermodynamic steam trap with built-in strainer for use in applications with up to 62 barg differential pressure. It can be equipped with a bimetal air ring for better air ventilation

TD120

Thermodynamic steam trap with built-in strainer for use in applications with up to 120 barg differential pressure.

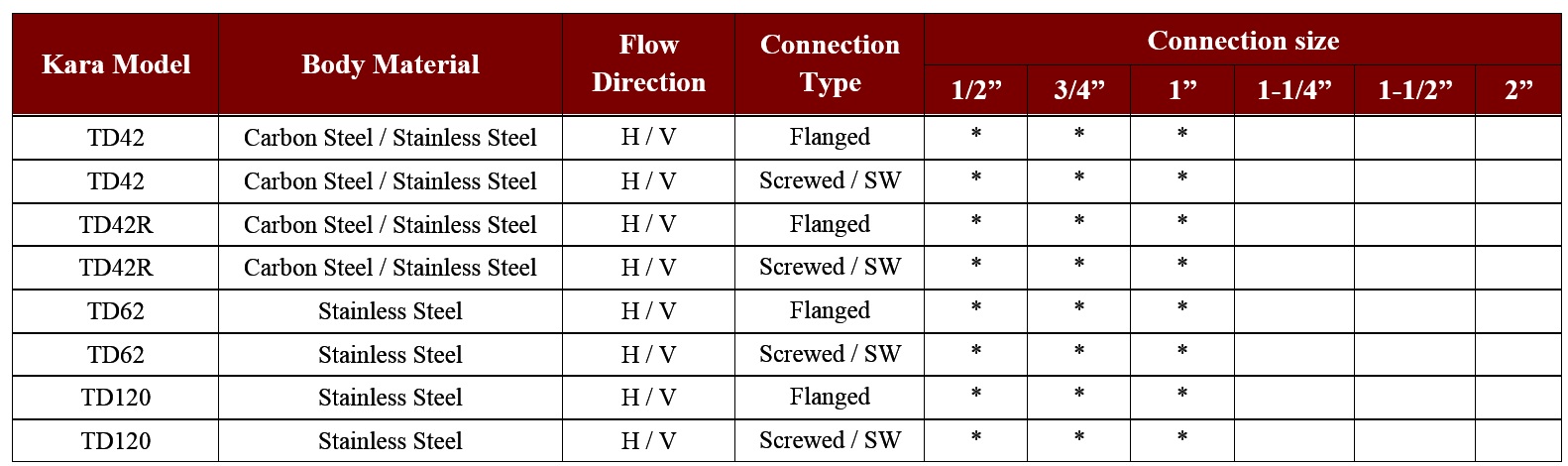

Also you can see the different types of Thermodynamic Steam Traps according to the connection and the model in the table below:

To know further about the thermodynamic steam traps we suggest you to Download Karajet's Catalogue for thermodynamic steam traps hereand also about thermodynamic steam traps.

Other connection sizes and standards are available on request. don't hesitate to contact us for further .assistance