Ejector

Hits : 4846 |

ejector definition is that the Ejector or jet pump is used for the conveyance, compression or mixing of gases, vapors, liquids.rather than mechanical parts, serve as the motive medium. ejectors are "Pumps without moving parts." ejector is used in a wide range of applications to generate a suction force and steam jet ejectors are used to create vacuum (vacuum ejectors) This suction force may be used to create vacuum and/or draw a secondary fluid. Pressurized Liquid, Gas or Steam could be used as the motive medium, while any liquid, gas or steam can be introduced as the suction fluid which includes wide range of applications.

We suggest you to read the "more details"part in order to know more about the ejectors.

?What is Ejector

"Jet pumps" or "vacuum ejectors" are devices for the conveyance, compression or mixing of gases, vapours, liquids or solids. Liquids, gases or vapours, rather than mechanical parts, serve as the motive medium.They are "Pumps without moving parts.

Numerous options for the motive medium result in an exceptionally wide range of uses. Besides many other applications, however, generating vacuum has . always remained the principle duty of these devices.between the different types of ejectors the vacuum ejector and the steam ejector are more useful in the petrochemical units and other related industries, however the jet ejectors are very similar to vacuum pumps and vacuum compressors but these jet ejectors have no moving parts so it makes them suitable for creating vacuum and also conveyance, mixing the gases also steam jet .ejectors can be useful in compressing the vapors and steam

Ejector Operation:

Ejector Operation:

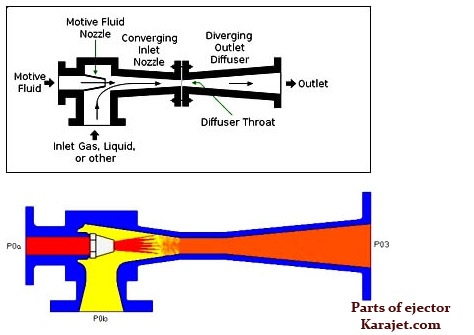

Ejector principle is that the vacuum ejector operates by the conversion of pressure energy into velocity in suitable nozzles. The principle of jet pumps is the entrainment and acceleration of the surrounding gas or liquid by the high velocity jet of motive liquid or gas emitted from the motive nozzle. The result of this action is a mixture of the driving and entrained fluids, the velocity of which is the practical application of this principle requires a simple apparatus, which normally consists of only three main parts:

Suction head (1)

Motive nozzle (2)

Diffuser or mixing nozzle (3, 4 and 5)

reduced and the pressure increased in a second nozzle.

Here in Karajet we design all different types of Steam jet ejector, Gas jet ejector, Liquid jet ejector and Vacuum systems For our customers’ more convenience we offer online calculation service if you want to choose a steam jet ejector or vacuum ejector you can use our website to suggest us your project.

We suggest you to read our catalog in order to become more familiar with our ejectors

you can download our catalog here

The flow channel of the mixing nozzle consists of a part converging in the direction of the flow (the inlet cone), a cylindrical piece (the throat) and a diverging part (the outlet cone).

The flow channel of the mixing nozzle consists of a part converging in the direction of the flow (the inlet cone), a cylindrical piece (the throat) and a diverging part (the outlet cone).

Jet pumps have three connections:

Connection A for the motive medium with the highest pressure, P1, and flow rate, M1;

Connection B for the suction medium with the lowest pressure, P0, and flow rate, M0;

Connection C for the discharge of motive and suction media with a medium pressure, P, and flow rate, M

The flow rate at the discharge is the sum of the suction and motive flow rates:

M = M0 + M1; P0 < P < P1

The suction medium passes through the suction nozzle, into the head of the jet pump. The motive medium is expanded, after passing through the motive nozzle, where the pressure energy is transformed into kinetic energy. This is the zone of lowest static pressure corresponding, more or less, to the suction pressure the pump has to provide. The energy stream so produced impinges with and conveys the suction medium coming from the suction connection B into the pump head, accelerating it into the inlet cone of the mixing nozzle. After passing through the throat of the mixing nozzle, into the diffuser, the kinetic energy of the mixed vapour stream is gradually converted back into potential energy, i.e. the medium is compressed to a higher discharge pressure. The pressure increase from suction pressure, P0, to discharge pressure, P, is equal to the delivery height or the pressure difference, ΔP, of the pump. The ratio P/ P0 corresponds to the compression ratio of a pum.

Order :

For the most effective design of a jet vacuum pump the following data are required:

-

Suction medium

- Composition, mol mass [kmol/kg]

- Suction flow, M0 [kg/h or kg/s]

- Suction pressure, P0 (absolute pressure) [mbar]

- Temperature, T0 [°C]

- Counter pressure, P (absolute pressure) [mbar]

-

Motive medium

- Pressure, P1 (over pressure or absolute pressure) [bar]

- Temperature, T1 [°C]

-

Cooling medium

- Temperature [°C]

- Head pressure [bar]

:Advantages of jet ejectors

- Simple construction

- Operationally safe

- Low wear and tear, resistance to corrosion and long life if appropriate material is chosen

- Suitable for vacuum up to 0.01 mbar (abs.)

- Combination with mechanical vacuum pumps

- Available in a wide range of materials (ensures compatibility with the process streams)

- No moving parts (enable trouble free, continuous operation)

- Almost any vacuum duty can be accommodated from small to large suction flows (10 m3/h to 2,000,000 m3/h)

- Low maintenance costs

- Reliable operation (minimizes plant down times)

- Low operating costs as a result of expert design which matches system requirements perfectly

- Easy installation

- Quick start-up

What are ejector Applications?

Jet vacuum pumps are used to create and maintain the vacuum in evaporators, driers, in distillation and rectification plants, and in the processes of freeze drying, poly-condensation, degassing and deodorizing.

Typical applications are:

- Deaeration of turbine condensers

- De-humidification of tobacco

- Manufacture of film in the plastics industry

- Production of urea

- Extruder degassing

- Drying processes

- Deodorizing edible oil

- Steel degassing

- Chemical industry

- Water desalination

- Vacuum distillation

- Natural gas exploitation and processing

:Our jet Ejector Advantages

KARAJET is the sole designer and manufacturer of all types of single and multi-stage ejectors in Middle-East. We have more than two decades experience in the energy market and more than 35 power plant units have been equipped with our vacuum systems so far. Our company is one of the most well-equipped ejector and vacuum system manufacturers around the world which has full in-house control over designing, manufacturing and testing procedures. As a Knowledge-Based Company with an official degree of technology from Iranian Ministry Of Science, Research & Technology, we are eager to supply our products to projects in Middle-East and CIS countries. Planning and equipping the factory with the variety of machineries and testing facilities, after more than two decades of uninterrupted activity, we have become one of the most prominent manufacturers in terms of quality in the global market.