Orifice Plate

Hits : 4890 |

Of the various types of head flow meters, the orifice plate is the most common. This is basically a machined metal plate with a round hole or orifice, through which fluids flow. Orifice plates cover a wide range of applications of fluid and operating conditions.

What is an orifice plate?

Orifice plates offer acceptable uncertainties at comparatively lower cost.

An orifice meter consists of a flat plate that has a sharp-edged hole accurately machined in it and placed concentrically in a pipe. As liquid flows through the pipe, the flow suddenly contracts as it approaches the orifice and then suddenly expands after the orifice back to the full pipe diameter. This forms a vena contracta or a throat immediately past the orifice. This reduction in flow pattern at the vena contracta causes increased velocity and hence lower pressure at the throat, similar to the venturi meter, discussed previously. The pressure difference at the throat can then be used to measure the liquid flow rate. Because of the sudden contraction at the orifice and the subsequent sudden expansion after the orifice, the coefficient of discharge C for the orifice meter is much lower than that of a venturi meter or a flow nozzle.

DESCRIPTION AND FEATURES

The orifice plate is manufactured from sheet metal. It is a flat circular plate with an outer diameter greater than the inner diameter of the process pipe into which it is to be fitted. An orifice meter consists of an orifice plate, a holding device, upstream downstream meter piping, and pressure taps. An orifice plate installed without specified upstream and downstream lengths of pipe controlled to close tolerances and/or without properly made pressure taps (usually flange) is not a “legitimate” flow meter; it must have specific tests run to determine its calibration. Since this is not economical, almost all orifice systems are built to meet the standard(s). This allows calculations to be made with specified tolerances.

Types of orifice

From a construction point of view orifice plates for measurement can be divided into the following:

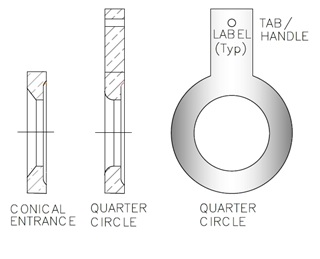

- Concentric orifice: As the name implies, this has its hole or orifice concentric with the main thin circular plate. Concentric orifice plates represent the majority of plates used in all orifice-based devices. They must have an upstream edge that is very sharp and square. The thickness and material are guided by the flow conditions and the fluid that it has to handle. There are a number of varieties:

- Concentric square edge: Where the bore is sharp-edged on the inlet and parallel or chamfered on the outlet

- Concentric conical: concentric conical entry orifice plates have a bore with a conical inlet section and a parallel outlet section.

- Concentric quarter circle: These types of orifice plates have a bore with an inlet in the form of a radius

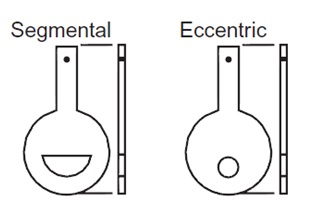

- Eccentric orifice: Eccentric orifices are used for low-viscosity liquids carrying carry solids. These are also used for flow measurement of gas-carrying liquids. The bore of the eccentric orifice is a circular hole in the plate, adjacent to the pipe wall to give free passage to solids.

- Segmental: The bore of segmental orifice plates is in the shape of a segment of a circle with its curved edge adjacent to the pipe. Segmental orifice plates are suitable to measure the flow of light slurries and fluids with high concentration of solids.

The use of eccentric and segmental orifices is preferred when horizontal meter runs are required for fluid flow containing extraneous materials, and there is the possibility of plugging up the concentric orifice.

Advantages of an orifice plate

- No moving parts

- Robust in construction

- Available in a large range of sizes and beta ratios

- Very economical

- Easy installation

- Prices do not change drastically with size

- Suitable for most of commonly used fluids

- Easy design and implementation

Limitations of orifice plates

- Orifice plates show high permanent pressure loss (PPL) and hence have a higher power requirement.

- Accuracy is at best within 2%-3%, with turndown maximum. Accuracy is affected by density, pressure, and viscosity fluctuations.

- Viscosity limits the measurement range.

- A concentric orifice is not suitable for liquids with dirt or slurry application.