Steam jet ventilator

Hits : 1454 |

Steam jet ventilators convey air, gases and vapours against small pressure differences up to approximately 500 mbar . In steam jet ventilators live steam expands through the inlet nozzle, issuing at high velocity.

read "more detail" to become more familiar with steam jet ventilators.

Steam jet ventilator

Steam jet ventilator :

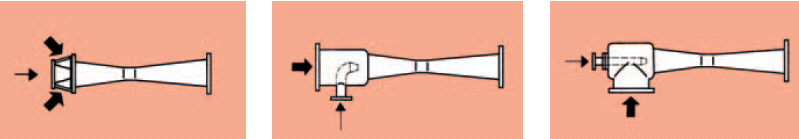

In steam jet ventilators live steam expands through the inlet nozzle, issuing at high velocity. The powerful suction thus produced entrains air or vapours via the suction connection. The suction medium, air, gas or vapour is either drawn in from the surrounding atmosphere or from the suction housing, depending on the type of ventilator construction used.

The achievable pressure difference between the suction pressure and discharge pressure is the compression of the steam jet ventilator.

We recommend you to learn more about steam jet ventilators, by looking at our catalog here :

Karajet Steam jet ventilators Catalog

Advantages

- An almost unlimited life when a suitable material of construction is chosen

- No moving parts

- Maintenance free

- Low priced

- Quickly and easily put into operation

- Manufactured from various materials of construction

- Installed in virtually all situations

- Larger compression (difference between suction and back pressure) than liquid jet ventilators

Applications

Steam jet ventilators convey air, gases and vapours against small pressure differences and are used, e. g., to:

- To draw waste air, bad-smelling gases and vapours from working and storage areas

- To ventilate tanks, e.g. on ships

- As forced blast blowers, or stack ventilators for boiler burners

- To draw off and mix exhaust gases from the thermal afterburning

- A variety of processes such as degassing, drying, etc