Gas-jet-Compressors

Hits : 1965 |

What is difference between Gas-jet-Compressors and Gas-jet-vacuum pump? Gas jet vacuum pumps and air jet vacuum pumps operate on the same principle as all jet pumps: The pressure energy of the motive medium is converted into speed energy in the motive nozzle.

But we recommend you to read " more details " part if you are interested in more.

Gas-jet-Compressors

What is a gas jet compressor?

Gas jet compressor is very similar to Gas jet vacuum pumps and also instead of liquid or steam ,gas , or compressed air is used as the motive medium. This is particularly suitable where no steam is available or where compressed air or gas as motive medium offer advantages over steam.

We recommend you Karajet Gas jet Compressor if you want to know more about it .

Advantages

- Simple in construction

- No moving parts

- Little maintenance needed

- Comparatively low initial cost

- Wide range of materials such as steal, stainless steal, cast iron, bronze, Teflon and graphite

Where do we use Gas jet Compressor?

Gas jet compressors have extensive applications in natural gas industry. These include

- By means of natural gas under pressure (e.g. well pressure), they suck gas from underground reservoirs and compress the mixture to pipeline pressure.

- Mixing two different types of natural gas with different heating value in proportion to obtain a constant specific heating value for gas network.

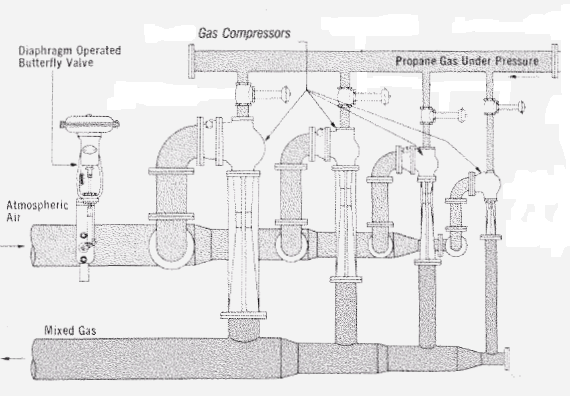

- In peak conditions in gas networks when there is natural gas shortage, Gas jet compressors utilizing evaporated liquefied gas (propane, butane, etc) serve to suck air from atmosphere and produce a mixture with similar characteristics to those of natural gas.

We can also use them

- In natural gas exploitation sites gas jet compressors motivated by the pressure side of turbo-compressors handling natural gas, suck the gas in their spiral housing at a pressure of 3 bar, and compress it to 16 bar, to prevent its leakage from shaft seal points crossing the housing.

- Propelling the gas stored in gas tanks at huge flow rates of thousands of cubic meters per hour

- Compressing the residual gases to atmospheric pressure during natural gas processing

Other application are

- Sucking in and mixing atmospheric refinery heating gases with process gases (exploitation of flare exhaust gases)

- Power generation

- Process industry

- Paper industry

- Petroleum production

Installation requirements

- In the case of gas jet compressors, to avoid reflux from pressure pipe into the gas tank, a non-return valve is needed on the suction pipe.