محصولات

- جت میکسر

جت میکسر

- استاتیک میکسر

استاتیک میکسر

- دی سوپر هیتر

دی سوپر هیتر

- اسپیرینگ هنگر-Spring hanger

اسپیرینگ هنگر-Spring hanger

- اجکتور

اجکتور

- سیستم تولید خلاء

سیستم تولید خلاء

- راپچر دیسک

راپچر دیسک

- سایلنسر

سایلنسر

- تله بخار

تله بخار

- تله بخار توپ شناور

تله بخار توپ شناور

- تله بخار ترمودینامیکی-دیسکی

تله بخار ترمودینامیکی-دیسکی

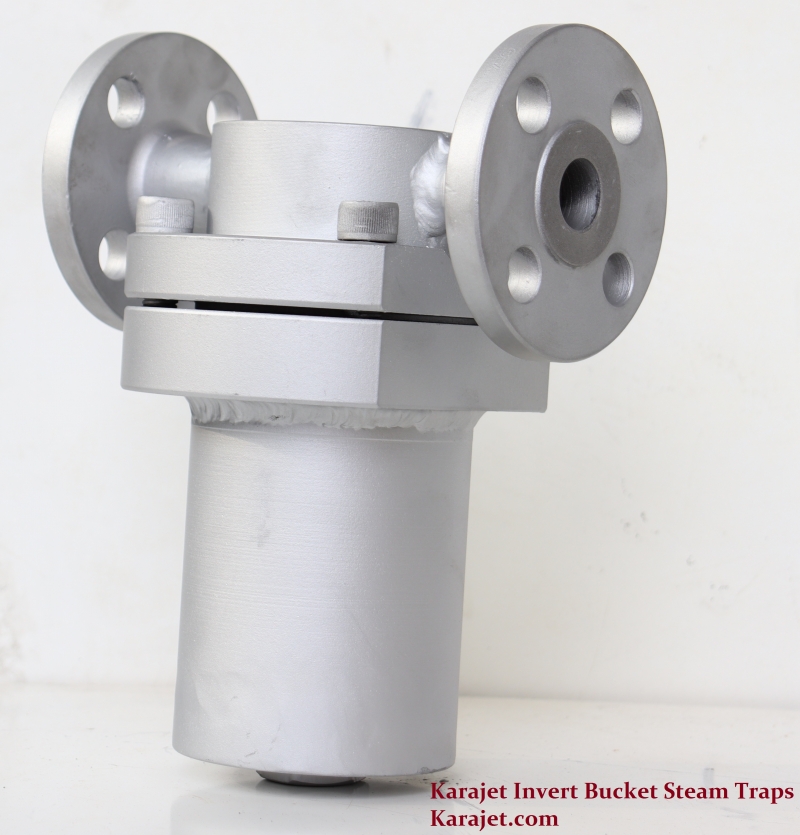

- تله بخار سطل معکوس

تله بخار سطل معکوس