محصولات

-

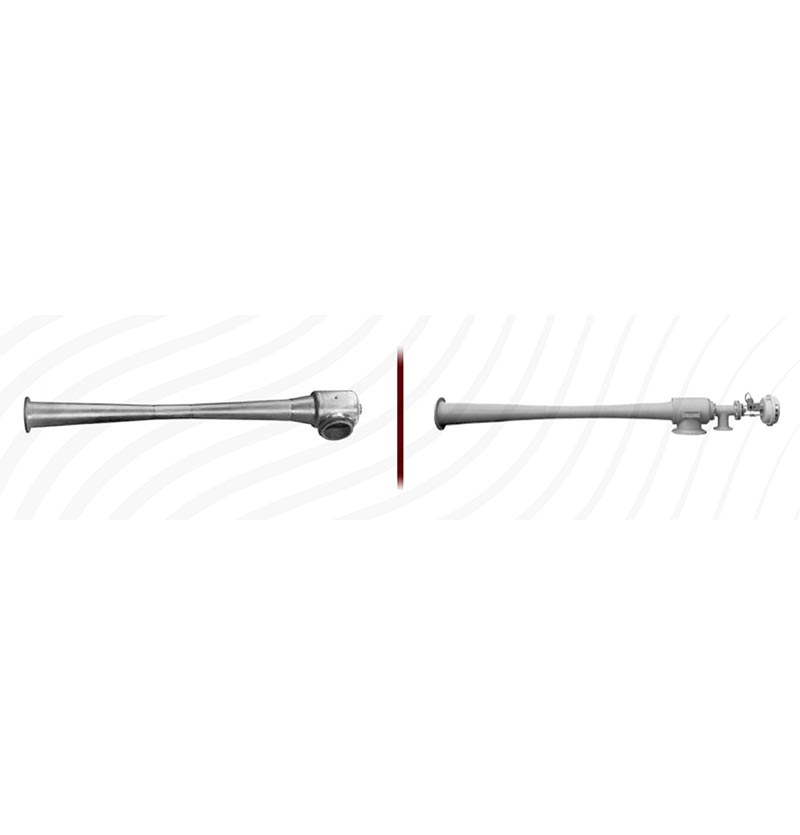

اجکتور

اجکتور

-

ونتیلاتور جت گاز

ونتیلاتور جت گاز

-

کمپرسور جت گاز

کمپرسور جت گاز

-

اجکتور خلاء جت گاز

اجکتور خلاء جت گاز

-

اجکتور بخار-مایع

اجکتور بخار-مایع

-

ونتیلاتور جت بخار

ونتیلاتور جت بخار

-

کمپرسور جت بخار

کمپرسور جت بخار

-

اجکتور خلاء جت بخار

اجکتور خلاء جت بخار

-

اجکتور مایع- مایع

اجکتور مایع- مایع

-

ونتيلاتور جت مايع

ونتيلاتور جت مايع

-

اجکتور مایع- جامد

اجکتور مایع- جامد

-

کمپرسور جت مایع

کمپرسور جت مایع